What can I do to prevent the generation of light-ends?

There are some ways to counteract the generation of light-ends.

One of the solution approaches is the partial exchange of the heat transfer oil used. In this case, part of the oil is replaced by fresh oil, whereby a certain percentage of the generated light ends will be discharged out of the system. With this, the flashpoint will increase to a higher level for a short time. However, this solution does not replace a flashpoint management and is only a short-term solution, mostly in case of an emergency. In addition, in some circumstances, the oil change is associated with a standstill of the system and – depending on the oil used – it causes high running costs.

A widely used approach approach for driving the light-ends out of the thermal oil is the so-called boiling out of the system. Even in connection with the already mentioned problem of cavitation, the heat transfer oil systems are boiled out already before the initial commissioning to drive out possibly existing water. Later, this is also done during the running operation to drive out light-ends possibly occurred. With this, it is avoided that light-ends get into the pump housing as a gas bubble and cause damages. Mostly, this process of boiling out is simply repeated in regular intervals; however, this comes again with longer standstills.

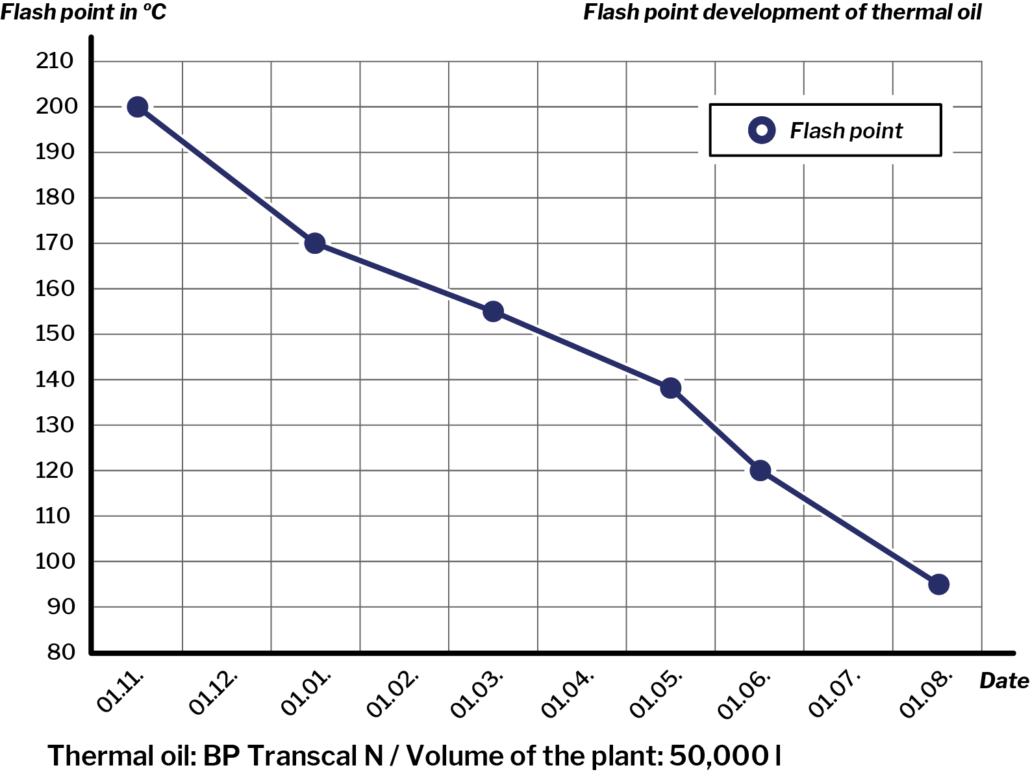

Otherwise, in addition to the methods introduced above, light ends can also be driven out of the system by means of distillation. Correctly intergraded, this solution has the advantage that it can be carried out during the running operation of the system. In this procedure the light ends are solved out of the heat transfer oil and separated. With this, the above-mentioned active flashpoint management can be implemented.