FAQ – NESS NALD250 / NALD250i

Active light ends removal system NALD250 / NALD250i for fast and flexible integration

In this FAQ-area, you can read some general questions and answers around the NALD250 / NALD250i of the NESS light ends removal systems, which advantage you can take of it and what you generally should consider for integration. In addition, it has to do with the infrastructure that should be given for successful operation.

- What does the NESS Light-ends removal system do?

- How do I integrate the NESS Light-ends removal system in my plant?

- Are there different light-ends removal systems available? And if yes, do we have to consider something?

- Do I need additional infrastructure for the operation of the light-ends removal system?

- For operation, additional nitrogen and cooling water are required. What do I have to consider and how high is consumption?

- The recommended inlet temperature in the NESS Light-ends removal systems is 250 °C. What happens, if this is below that?

- Is humidity removed from the thermal oil in addition to the light-ends?

- What happens with the separated light-ends and what do we have to observe?

- What is the difference between the active light-ends removal systems NALD250 and NALD250i?

- What do I have to consider in the place of installation of the NALD250 / NALD250i? Which conditions must be met?

What does the NESS Light-ends removal system do?

The NESS Light-ends removal system is a product in the NESSessities concept which constantly increases safety, availability, durability and efficiency in thermal oil systems. One of the 3 most important factors for a good quality is a stable flashpoint. The NESS Light-ends removal system helps you ensuring this permanently.

the flashpoint is an important factor for good quality

Back to Index

How do I integrate the NESS Light-ends removal system in my plant?

No problem at all! Like all NESSessities, also the NESS Light-ends removal system is designed as an individual module. Existing processes are not influenced. because the light-ends removal takes place in the bypass flow. This concept allows the relatively easy retrofitting also for already existing systems.

in the bypass flow of the system

Back to Index

Are there different light-ends removal systems available? And if yes, do we have to consider something?

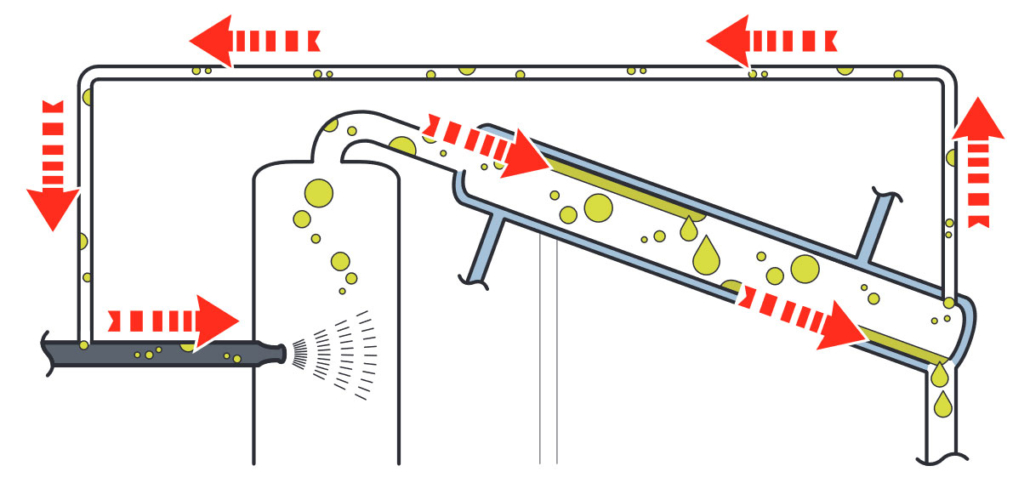

Basically, there are two types of systems for light ends removal at NESS: a passive system and an active system.

The passive light ends removal system works with gravity. That means that it must be installed at least 2m above the highest point of the system (mostly the expansion tank). This often requires an additional steel structure which would preferably seem the thing to do when a new plant is planned and not for retrofitting. The solution is feasible for systems with up to 110,000 litres of thermal oil.

The active light ends removal system is very flexible because it is equipped with its own pump pump and a frequency converter. Therefore, among others, its implementation in existing systems can be planned better and it can also be used optimally for systems with more than 110,000 litres of thermal oil.

What product solutions are available for your system you will read here

Back to Index

Do I need additional infrastructure for the operation of the light-ends removal system?

Besides a certain inlet pressure of the thermal oil, nitrogen, cooling water and control air will be required in addition. Due to its own pump and control unit, the active light ends removal system certainly needs the respective power supply.

Please find more details here.

Back to Index

For operation, additional nitrogen and cooling water are required. What do I have to consider and how high is consumption?

Nitrogen is always required for the operation of the light-ends removal system. This is required for the intertisation and the generation of overpressure within the system. Consumption depends on the quantity of light-ends in the oil.

| Nitrogen cylinder (50 litres / 200 bar) | |

| With fresh oil | approx. 6 days |

| With used oil | approx. 2 days |

To ensure the continuous provision of nitrogen and simultaneously to reduce the running costs, we recommend using a nitrogen generator with a 750-l nitrogen tank.

Cooling water is always required for the operation of the light ends removal systems. While the passive light ends removal systems mostly work without cooling water (due to air cooling), it is highly recommended for active light ends removal systems. In warmer regions with ambient temperatures of more than 25ºC it is even always required. Water cools the condenser in which the hot, gaseous light ends are cooled down and condensed.

| Volume flow of cooling water | 200 litres / hour |

Back to Index

The recommended inlet temperature in the NESS Light-ends removal systems is 250 °C. What happens, if this is below that?

If the recommended inlet temperature is below 250 °C, removal of the light ends is still possible, but it will be clearly worse than at the recommended temperature.

Back to Index

Is humidity removed from the thermal oil in addition to the light-ends?

Indeed, also water is removed from the thermal oil additionally to the light-ends. The evaporation temperature of water is approx. 100 °C and therefore, it is separated like the light-ends.

Back to Index

What happens with the separated light-ends and what do we have to observe?

The separated light ends are collected in the light-ends collecting tank. This contains a volume of 70 litres.

It must be disposed of in accordance with the local regulations. We recommend storing in a metal tank outside the building in an explosion-proof room. The metal tank must always be kept closed and emptied by a company specialised in disposal.

Back to Index

What is the difference between the active light-ends removal systems NALD250 and NALD250i?

Technically seen, the design of the two products is quite similar. These two solutions distinguish by the partial return flow of light-ends gases in the NALD250i. By additional returning of low-boiling gases in the distillation circuit of the system, the system becomes a pure turbo-remover. For this reason, compared to the normal NALD250, the light ends removal can run faster for up to 5x depending on the individual parameters, e.g. temperature, type of oil, and system size.

Due to this extremely efficient working principle the NALD 250i is further ideally suitable for the rotating operation of multiple separated thermal oil systems up to 400,000 litres of total volume.

Back to Index

What do I have to consider in the place of installation of the NALD250 / NALD250i? Which conditions must be met?

Principally, the light ends removal system should be installed in a well-ventilated area. The exhaust duct must safely lead into the open air and the deflagration flame arrester that comes with the system must be installed at the end. The area around this opening must be free from ignition sources.

The system is also suitable for outdoor installation. However, it should be roofed to protect it from weather, e.g. by a penthouse roof, to protect the components and the electronic circuits.

It should be connected to the flow line of the thermal oil system. The return flow in the thermal oil system can be led as desired.

With this, pay special attention to the following interface parameters:

| Connection valve – thermal oil (inlet and outlet) | Nominal diameter DN40 |

| Cooling water valves | Nominal diameter DN20 |

| Thermal oil – flow | 2 – 4 bar |

| Thermal oil – return flow | 0 – 3 bar (max. 4 bar) |

| Recommended inlet temperature | 250 °C |

| Control air | 4 – 6 bar (g) |

| Nitrogen supply | > 3 bar min. 99.0% N2 |

| Cooling water | 0,5 – 1 bar |

| Three-phase connection | appr. 5 kW |

Back to Index

Other FAQ topics that might interest you

NESS NLPA150 / NLPA250

Passive light ends removal system

NLPA150 / NLPA250 as special solution