FAQ – NESS NEA / NEWM

Fire extinguishing system NEA / NEWM for fighting against fires in heaters

In this FAQ-area, you can read some general questions and answers around the NESS extinguishing systems NEA / NEWM, which advantage you can take of it and what you generally should consider for integration. In addition, it has to do with the infrastructure that should be given for successful operation.

- What does the NESS Argon Extinguishing System do?

- How do I integrate the NESS Argon Extinguishing System in my system?

- What do I have to observe for the integration of the NESS Argon Extinguishing System (NEA)?

- What does the NESS Extinguishing and Cooling System do with water mist?

- Isn’t the use of water for extinguishing a fire caused by thermal oil dangerous?

- How do I integrate the NESS Extinguishing and Cooling system in my heater?

- What do I have to observe for the integration of the NESS Extinguishing and Cooling System?

- Do I need additional infrastructure for the operation of the Extinguishing and Cooling System?

What does the NESS Argon Extinguishing System do?

The NESS Argon Extinguishing System (NEA) flushes the heater with inert gas (argon) which is clearly lighter than air and so it displaces and extinguishes the fire. The extinguishing system is part of the NESSessities concept which constantly increases safety, availability, durability and efficiency in thermal oil systems.

Back to Index

How do I integrate the NESS Argon Extinguishing System in my system?

No problem at all! Like all NESSessities, also the NESS Argon Extinguishing System is designed with practical orientation. Often, the NESS heaters already have integration points, where the integration is easy to make. In some circumstances, the subsequent integration in heaters of other manufacturers can be realized. Certainly, be would be happy to check the respective integration possibility for you.

Back to Index

What do I have to observe for the integration of the NESS Argon Extinguishing System (NEA)?

Probably, the most important thing is the quantity of required argon adapted to the respective heater size that must be made available. For this purpose, beside the heater volume it is also required to calculate the volume of the air- and flue-gas leading parts of the system / channels and to use these as basis for the dimensioning of the system.

Furthermore, in addition to the manual switching on of the argon Extinguishing System, also the integration in the existing safety switch circuits of the heater is needed.

Back to Index

What does the NESS Extinguishing and Cooling System do with water mist?

As the name already says, apart from the actual extinguishing of the fire, the source of fire will be cooled additionally by the fine water mist. The extinguishing and cooling system with water mist (NEWN) is part of the NESSessities concept which constantly increases safety, availability, durability and efficiency in thermal oil systems.

Back to Index

Isn’t the use of water for extinguishing a fire caused by thermal oil dangerous?

A direct water jet to extinguish the fire would be dangerous. It could evaporate instantaneously if it contacts the heat of the thermal oil leakage and cause damage.

Therefore, the NESS extinguishing system counts on a very fine water mist that forms an inert pad on the fire and smothers it. The water mist is sprayed by a special nozzle that is moved into the heater chamber if activated.

Back to Index

How do I integrate the NESS Extinguishing and Cooling system in my heater?

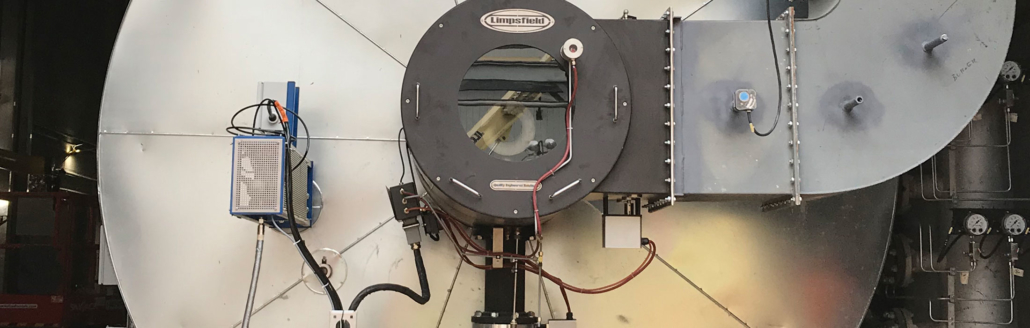

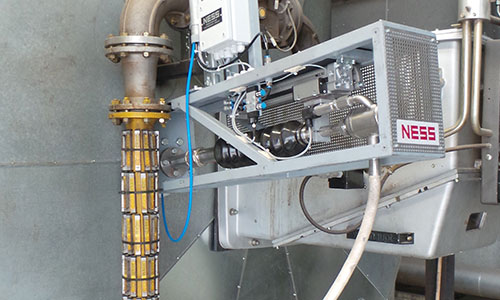

No problem at all! Like all NESSessities, also the NESS Extinguishing and Cooling System is designed with practical orientation. It consists of two parts, i.e. the lance unit which moves into the heater and extinguishes the fire and the control unit. The NESS Extinguishing and Cooling System has its own control unit for process control and process monitoring.

Often, the NESS heaters already have integration points, where the integration is easy to make. In some circumstances, the subsequent integration in heaters of other manufacturers can be realized. Certainly, be would be happy to check the respective integration possibility for you.

Back to Index

What do I have to observe for the integration of the NESS Extinguishing and Cooling System?

The size of the extinguishing system depends on the heater volume. There are two different manufactured sizes.

| Small system (NEWM1) | Water flow rate | approx. 1300 l/h |

| Cooling capacity | appr. 800 kW | |

| Steam volume | approx. 2100 m3/h | |

| Large system (NEWM2) | Water flow rate | approx. 4500 l/h |

| Cooling capacity | appr. 2800 kW | |

| Steam volume | approx. 7300 m3/h |

The continuous supply of fire-fighting water must be ensured.

Back to Index

Do I need additional infrastructure for the operation of the Extinguishing and Cooling System?

For the control unit observe the following items:

| Compressed air | 6 bar(g), dry and oil-free, quality class 2, ANSI/ISA-7.0.01-1996, 1 connection ¾“ sleeve |

| Water | Pressure of 4-6 bar(g), 10°C-40°C, drinking water quality min. 7 m3/h for large system min. 2,5 m3/h for small system |

The water connection can or shall be connected to two independent water sources (redundant connection).

Back to Index

Other FAQ topics that might interest you

Extinguishing of fires caused by the heater

What do I have to observe for fires caused

by the heater and how to proceed best?