FAQ – NESS Pump Monitoring (NPCL/NPCV/NPCT)

Pump monitoring (NPCL/NPCV/NPCT) for easy integration

In this FAQ-area, you can read some general questions and answers around the NESS pump monitoring system (NPCL/NPCV/NPCT), which advantage you can take of it and what you generally should consider for integration. In addition, it has to do with the infrastructure that should be given for successful operation.

- What does the NESS Pump Monitoring System do?

- How do I integrate the NESS Pump Monitoring in my system?

- Which and how many sensors must be integrated?

- Is it necessary to monitor all three parameters, or can I decide on single solutions?

- Which technical characteristics does the leakage monitoring have (NPCV)?

- Which technical characteristics does the vibration monitoring have (NPCV)?

- What do I have to observe for the Bearing Temperature Monitoring (NPCT)?

What does the NESS Pump Monitoring System do?

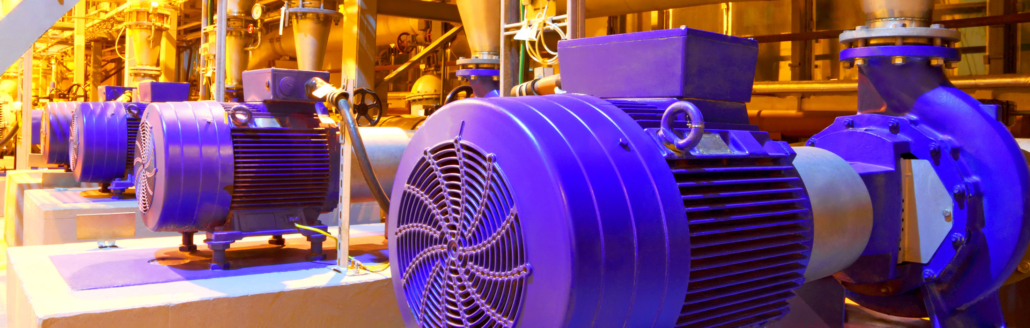

The NESS Pump Monitoring System consists of three modules with which it measures the most important parameters – leakage (NESS NPCL), pump vibration (NESS NPCV) and bearing temperature (NESS NPCT) – during the operation of the pump. The NESS Pump monitoring system is part of the NESSessities concept which constantly increases safety, availability, durability and efficiency in thermal oil systems.

Back to Index

How do I integrate the NESS Pump Monitoring in my system?

No problem at all! Like all NESSessities, also the NESS Pump Monitoring System is designed with practical orientation. The modules can be used independently from the manufacturer and are integrated in existing system control. This concept allows the relatively easy retrofitting also for already existing systems.

Back to Index

Which and how many sensors must be integrated?

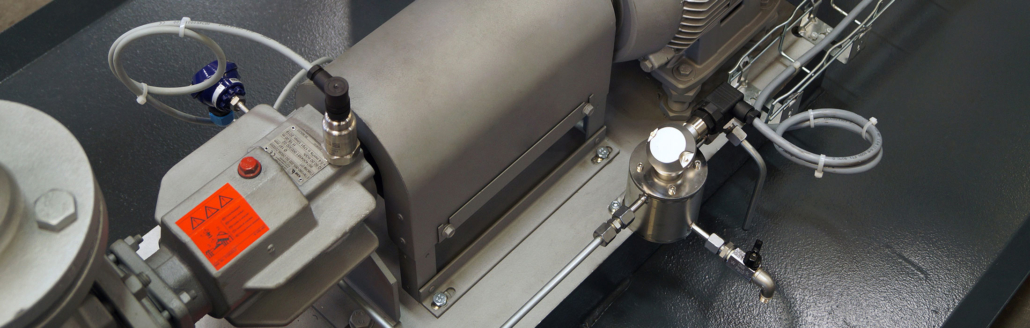

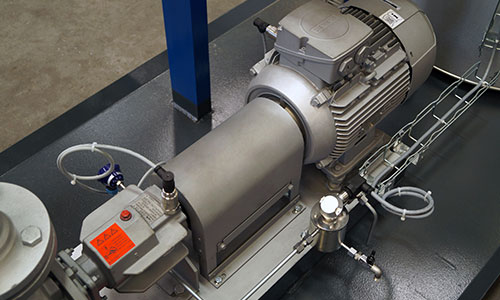

All-in-all 4 sensors must be integrated for monitoring. The leakage monitoring (NPCL) is a small stainless-steel container that is mounted on the base plate of the pump. Filling level and temperature are measured on this container to be able to distinguish between cold and hot filling up (pumps can have a normal leakage due to operation). The vibration monitoring (NPCV) consists of 1-2 sensors that are mounted on motor housing / or pump (depending on the design of the coupling and the maintenance strategy). The bearing temperature (NPTC) is mounted on the bearing carrier of the pump.

Back to Index

Is it necessary to monitor all three parameters, or can I decide on single solutions?

Because it is a modular system, it is possible to use leakage, pump vibration, or bearing temperature as a single monitoring solution. For safety-related points of view however, we recommend the complete monitoring of the parameters.

Back to Index

Which technical characteristics does the leakage monitoring have (NPCV)?

| Mechanical Connections | Precision steel pipe Ø8 x 1 with Ermeto screwed connection G¼“ |

| Dimension | Approx. 130 x 156 x 180mm (without fastening parts and screwed connection |

| Container capacity | 0.3 litres |

| Material | Stainless steel |

| Voltage | V = 24 V DC |

| Current | I ≤ 0.2 A |

It is connected by precisions steel pipes with Ermeto screwed connection. These are included in the scope of delivery as mounting set in two different variants (depending on type of pump and the local conditions).

Back to Index

Which technical characteristics does the vibration monitoring have (NPCV)?

| Measuring range | 0 – 12 mm/s ± 10% |

| Frequency range | 10 Hz to 1 kHz ± 5% – ISO10816 |

| Insulation | Sensor basis insulated |

| Housing material | Stainless steel |

| Sensor element/design | Piezoresistive / compression |

| Tightening torque | 8 Nm |

| Weight | approx. 150g |

| Current output | 4 – 20 mA DC; 2-core connection |

It is mounted to the pump by a threaded part that is included in the scope of delivery as mounting set depending on the type of pump.

Back to Index

What do I have to observe for the Bearing Temperature Monitoring (NPCT)?

| Measuring resistance | Pt100 |

| Housing material | Stainless steel |

| Temperature range | Depending on size up to 500°C |

| Installation length | 10 mm |

| Current output | 2-core connection |

The bearing temperature monitoring unit consists of a protective pipe with installed measuring elements. They reliably measure the bearing temperature and record an unwanted increase of temperature. The sensor to be mounted depends on the manufacturer of the pump and the pump size and is directly screwed in the bearing carrier.

Back to Index